Unwinding the Enigma of Porosity in Welding: Tips for Reducing Issues and Maximizing Quality

In the detailed world of welding, porosity continues to be a persistent obstacle that can significantly impact the high quality and stability of bonded joints. As we dig right into the depths of porosity in welding, uncovering the tricks to its avoidance and control will certainly be vital for professionals seeking to understand the art of high-quality weldments.

Comprehending Porosity in Welding

Porosity in welding, an usual issue come across by welders, describes the existence of gas pockets or gaps in the welded material, which can jeopardize the stability and top quality of the weld. These gas pockets are typically trapped during the welding procedure because of different factors such as incorrect protecting gas, infected base products, or incorrect welding specifications. The formation of porosity can weaken the weld, making it vulnerable to breaking and corrosion, inevitably bring about architectural failings.

Understanding the origin of porosity is crucial for welders to effectively stop its occurrence. By acknowledging the relevance of keeping proper gas securing, making sure the cleanliness of base products, and optimizing welding setups, welders can dramatically minimize the possibility of porosity formation. Furthermore, utilizing strategies like pre-heating the base material, using appropriate welding methods, and carrying out detailed inspections post-welding can additionally aid in decreasing porosity problems. In general, an extensive understanding of porosity in welding is vital for welders to create premium and sturdy welds.

Typical Reasons For Porosity

When examining welding processes for potential high quality concerns, understanding the common reasons of porosity is important for preserving weld honesty and protecting against structural failures. Porosity, characterized by the presence of cavities or voids in the weld steel, can considerably jeopardize the mechanical properties of a bonded joint.

Another common source of porosity is the visibility of dampness and pollutants externally of the base steel or filler product. When welding materials are not effectively cleaned or are subjected to high levels of humidity, the vaporization of these contaminants throughout welding can develop gaps within the weld bead. Furthermore, welding at inappropriate parameters, such as exceedingly high traveling speeds or currents, can generate excessive disturbance in the weld pool, trapping gases and triggering porosity. By addressing these typical reasons via appropriate gas shielding, material prep work, and adherence click this site to ideal welding parameters, welders can lessen porosity and boost the quality of their welds.

Techniques for Porosity Avoidance

Executing efficient safety nets is essential in reducing the incident of porosity in welding procedures. One method for porosity avoidance is making certain correct cleaning of the base metal prior to welding. Impurities such as oil, oil, corrosion, and paint can cause porosity, so detailed cleansing making use of ideal solvents or mechanical techniques is important.

Another secret preventative procedure is the choice of the best welding consumables. Utilizing premium filler materials and shielding gases that are suitable for the base steel and welding process can substantially minimize the threat of porosity. In addition, preserving appropriate welding parameters, such as voltage, existing, take a trip speed, and gas flow rate, is crucial for porosity prevention. Deviating from the recommended setups can lead to incorrect gas coverage and inadequate combination, resulting in porosity.

Additionally, using correct welding strategies, such as maintaining a constant traveling rate, electrode angle, and arc length, can assist stop porosity (What is Porosity). Ample training of welders to guarantee they comply with best practices and top quality control procedures is also necessary in reducing porosity issues visit the website in welding

Finest Practices for Top Quality Welds

One trick method is maintaining proper sanitation in the welding area. Thoroughly cleansing the workpiece and bordering area prior to welding can help reduce these concerns.

An additional best technique is to meticulously pick the ideal welding parameters for the specific products being signed up with. Correct parameter choice guarantees ideal weld penetration, fusion, and overall top quality. Making use of high-grade welding consumables, such as electrodes and filler steels, can substantially affect the last weld top quality.

Relevance of Porosity Control

Porosity control plays you could try these out a crucial duty in making certain the stability and high quality of welding joints. Porosity, characterized by the presence of dental caries or spaces within the weld metal, can significantly compromise the mechanical residential properties and architectural stability of the weld. Excessive porosity damages the weld, making it a lot more vulnerable to cracking, deterioration, and general failure under functional tons.

Reliable porosity control is crucial for keeping the preferred mechanical properties, such as toughness, ductility, and toughness, of the bonded joint. What is Porosity. By minimizing porosity, welders can improve the overall quality and integrity of the weld, making sure that it meets the performance needs of the desired application

In addition, porosity control is important for attaining the desired visual look of the weld. Excessive porosity not just weakens the weld but likewise interferes with its visual charm, which can be essential in industries where appearances are very important. Appropriate porosity control strategies, such as using the appropriate securing gas, managing the welding parameters, and making certain appropriate sanitation of the base materials, are vital for creating top quality welds with minimal issues.

Conclusion

In conclusion, porosity in welding is a typical flaw that can endanger the top quality of the weld. It is essential to control porosity in welding to guarantee the stability and toughness of the final product.

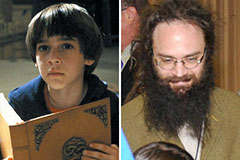

Barret Oliver Then & Now!

Barret Oliver Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!